Companies

How Digital Monitoring Products Turns Ideas Into Innovation

Listening to its customers is at the heart of the products developed by Digital Monitoring Products.

by Megan Price

Jan 2026

Digital Monitoring Products (DMP) has been part of Springfield’s business landscape since 1975, when Rick Britton began developing products for his father’s company, Atlas Security. That side project became its own operation, growing into a national manufacturer known for dependable technology and customer-focused design.

“Throughout the last 50 years, DMP has maintained its roots in the community and has remained a family business,” says Chuck La Tournous, director of marketing. “We’re known for putting the customer first. In fact, providing customer-driven products through listening and anticipating their needs is right in our mission statement.”

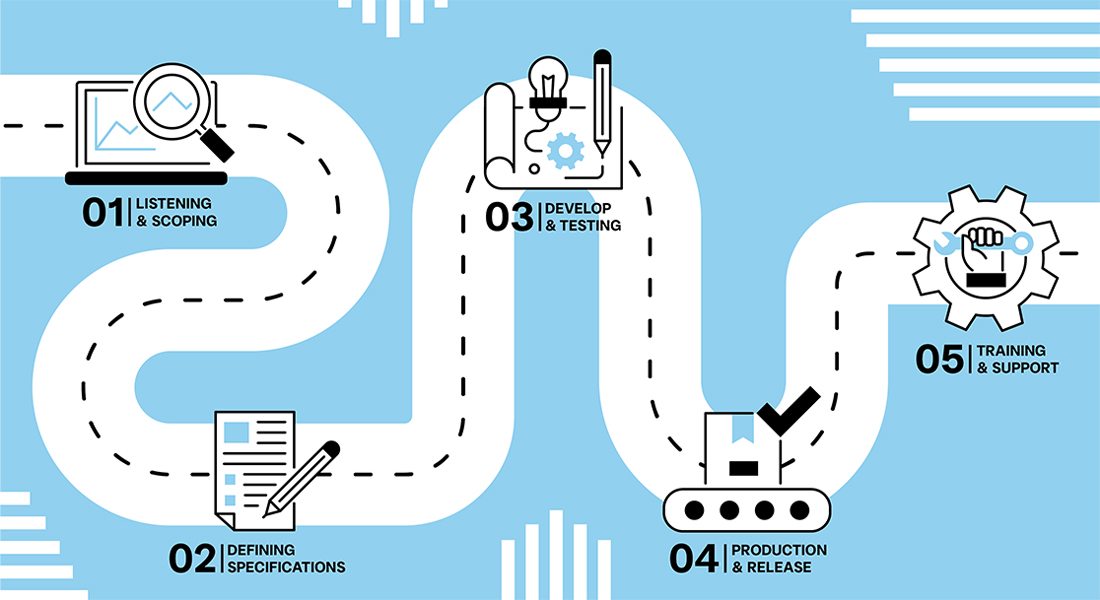

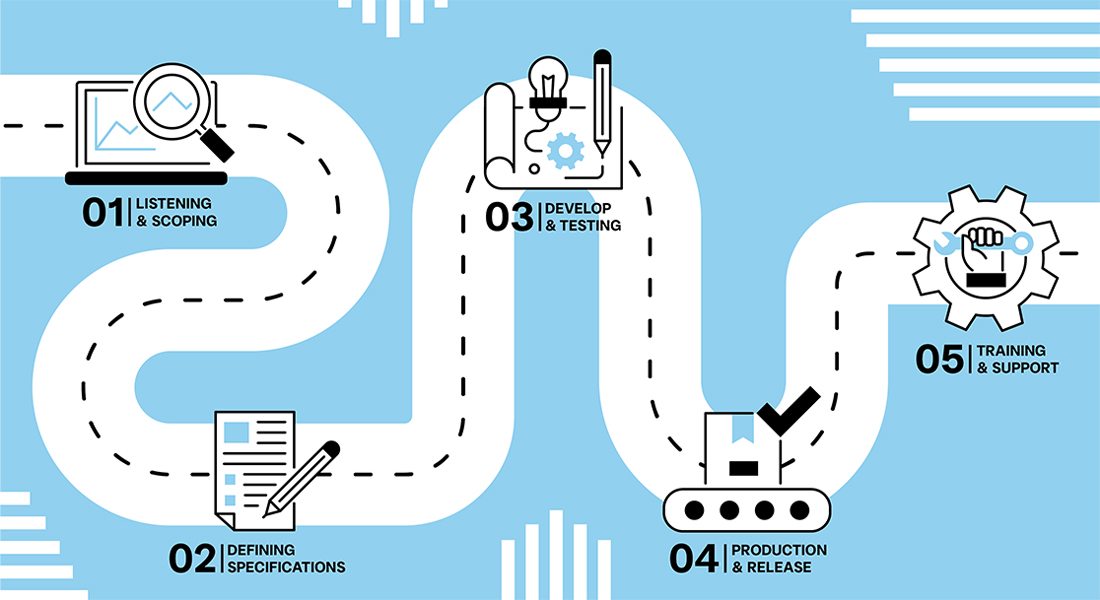

Step 1: Listening and Scoping

Every product starts with listening. DMP gathers customer feedback through trade shows, office visits and roundtable events to identify needs and trends happening in the security industry. That feedback is compiled into a document outlining what the new product or feature should accomplish. “With that high-level understanding of the need, we create a scoping document that allows us to communicate internally and ensure that leadership and team members are aware of new products and features we’re building,” La Tournous says. This step ensures everyone within the company is aligned before development begins.

Step 2: Defining the Specifications

Once the idea is approved, product managers take over. They define exactly how the product should look, act, and perform, documenting every requirement. “Product managers document the requirements of how the product or feature will look, act, respond, perform, and several other traits,” says La Tournous. They also estimate how many customers might adopt the new technology and what benefits it will deliver. If it doesn’t seem like a strong fit, DMP is willing to step back. “If we don’t think a project is going to meet customers’ needs, we may not proceed.”

Step 3: Developing and Testing

When the plan is finalized, engineers, developers and quality assurance specialists move the project into design and testing. Every part of the product is examined to ensure it meets DMP’s standards. “Products and features are tested in multiple ways to make sure they perform well both individually and as part of an integrated system,” La Tournous explains. The company also invites customers to test products in controlled lab settings. “We often make minor changes prior to launch based on feedback from our field testers.”

Step 4: Production and Release

Once testing is complete, production begins at DMP’s Springfield facility. “If it’s a new physical product we have built, we design test fixtures and determine how the product will be built on our manufacturing lines in Springfield,” La Tournous says. To ensure reliability, every item is tested before leaving the building. “We build our production lines around automated digital testing equipment so that testing is a normal step in our production process,” La Tournous says. “That allows us to test 100% of our products before they go out into the field.”

Step 5: Training and Support

After production, DMP’s technical documentation and marketing teams create installation guides, training resources and materials to promote sales and help the customers understand the product. The company employs about 380 people nationwide across engineering, manufacturing, product management and support roles. “The work we do protects people and property,” La Tournous says. “Our employees see the value in the work they do, and they see that the profit the company makes is both reinvested into developing new products and invested into giving back to the community.”